Trust Actian for manufacturing

The confidence to go from data to real-time decision for better business outcomes.

Why Actian for manufacturing

At Actian, we equip manufacturing leaders with a secure, unified data platform, enabling real-time insights while simplifying your tech stack. By breaking down data silos, our platform streamlines supply chain data, offering visibility into inventory, demand forecasts, and production schedules. Actian ensures manufacturing leaders have the confidence and connectivity needed for scalable, efficient, and data-driven decision-making.

Data drives manufacturing

Bringing you from data to decision with confidence.

Explore our process

All manufacturing begins with an idea, and ideas begin with data. Data mined from market trends and consumer behaviors—stored meticulously in and databases– informs the creation of new products during R&D, which transform from idea to design to reality.

Data collected from disparate sources and stored in databases is analyzed to identify opportunities for innovation and improvement.

Learn moreData from prototype simulations is integrated with project management systems to streamline design iterations and prototyping cycles.

Learn moreRDBMS databases structured for historical analytics models collect sales data, market trends, and resource availability data, which is then integrated with enterprise resource planning (ERP) systems to align production schedules with forecasted demand and resource availability.

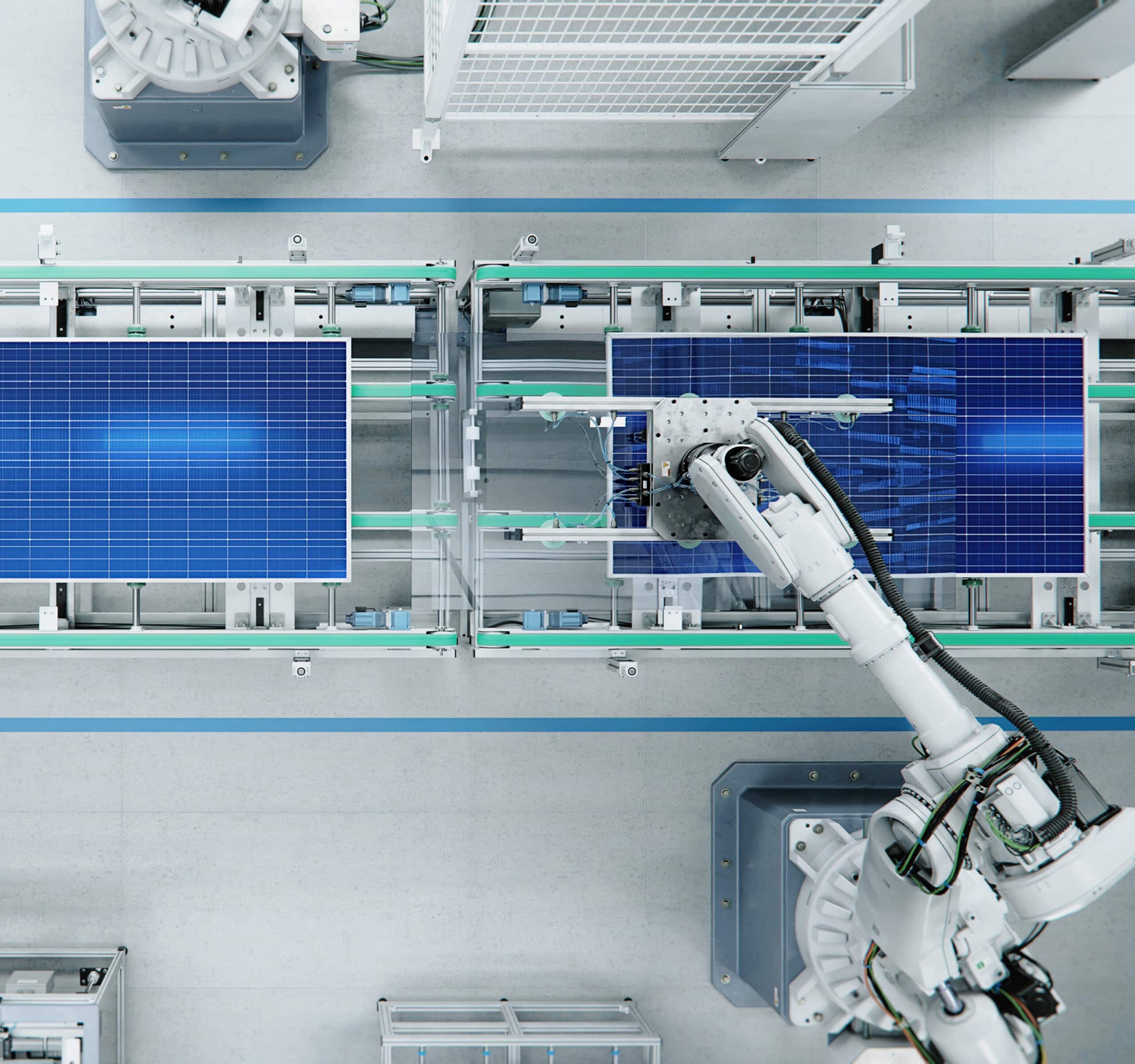

Learn moreEdge databases collect real-time data from IoT sensors on machinery and quality control systems, which then integrate with MES systems for real-time monitoring and control of manufacturing processes.

Learn moreNoSQL databases track inventory levels, shipping information, and route data to integrate with logistics and warehouse management systems for route optimization and inventory management.

Learn moreExplore Actian manufacturing products

Use cases

No matter the challenge, Actian has a solution. From supply chain intricacies to production optimization, Actian delivers tailored solutions for every manufacturing need. Discover how we turn obstacles into opportunities, and data into decisions.

Quality optimization

Siloed data makes it difficult to get a full picture of production timelines and customer satisfaction. With Actian, you can access a single modular data management platform across your mobile, IoT, and remote factory systems, inline analytics on legacy transactional systems, and extract and combine data from these new sources and disparate SCM, HCM, MES, and other ERP systems to perform analytics in a data warehouse that generates new insights across your enterprise.

Product innovation

Accelerate product innovation and time to deploy, reduce maintenance costs, and optimize instrumentation and understanding of your factory floor and products with Digital Twins. Fully tap the potential of Digital Twinning with Actian’s real-time connected Cloud Data Warehouse and Zen Edge Data Management, using front-end IoT systems with back-end ERP, engineering, and production systems.

Sustainability with ESG

Focusing on your supply chain is key to the success of overall environmental, social, and governance (ESG) efforts. Customers trust Actian because we provide more than just a platform. Actian helps companies find enduring ways to conserve energy and materials to cause less harm to the environment, implement traceability, and preserve the integrity of human welfare.

Predictive maintenance

With Actian, developers and product managers can focus on coding the business and operational logic at the edge to collect and manage the right combination of data across mobile and fixed wireless networks. Support front-end data processing from legacy systems and newly developed IoT sensor grids to deliver insights at the points of action on your factory floor.

Modernize applications

Actian can provide you with a single modular data management platform across your mobile, IoT, and remote factory systems, inline analytics on legacy transactional systems, and extract and combine data from these new sources and disparate SCM, HCM, MES, and other ERP systems to perform analytics that generate new insights across your enterprise.

The future of manufacturing

Manufacturing is on the cusp of a revolutionary transformation, driven by the advent of Industry 4.0 technologies and the Internet of Things (IoT). Expect unprecedented levels of efficiency, customization, and automation, with an emphasis on sustainability and circular economy principles.